Singapore’s government has announced a new initiative to encourage the adoption of robotics and automation (R&A) solutions to improve productivity and reduce labour dependency in the local built environment (BE) sector.

Speaking at the ‘CEOs in Conversation’ during the recent International Built Environment Week (IBEW) 2021, Minister of State for National Development and Communications and Information, Tan Kiat How, invited R&A solution providers to participate in the Call for Proposals (CFP) for Integrated Robotics & Automation solutions by the Building and Construction Authority (BCA) and Infocomm Media Development Authority (IMDA).

“The government, through the BCA and IMDA scheme, will be supporting our built environment firms to adopt these solutions. These are commercially available solutions, for example, material transporter robots, precast automation systems, drones for facade inspections, and so on. We will be supporting up to 80% of qualifying costs to adopt these solutions,” said Mr Tan.

He explained that the launch of this initiative is “not just supporting our firms to adopt commercially available solutions, increasing productivity, and raising our standards. It is also about investing in early stage technology – R&D, for tomorrow.

“One good example is 3D concrete printing by HDB, with partners like NTU, Robin Village Development and Witteveen+Bos. 3D concrete printing reduces manpower for volumetric production and improves productivity at the worksite. But the technology is still very nascent. That is why HDB is taking the lead at the Centre of Building Research, to understand the technology, bringing in partners together to build an ecosystem, understand how it can be used and applied in Singapore for the future.”

“Another example of things we are working on is 5D BIM,” added Mr Tan. “I asked what is 5D BIM because it is the first time I have heard about it. I was told it is 3D BIM with the time component and the cost and budget component added. It harnesses computational power to automate workflows, and lets planners and developers and builders make better decisions, better predict material and labour costs, and supports tasks like planning, budget control, progressive payments, etc.

“All these tasks can be automated, and we can do things better. BCA is working with Hubble Pte Ltd and Rider Levett Bucknall on this project. This is one example of how we are investing in R&D under the Cities of Tomorrow (CoT) programme. So, for companies and solution providers, if you have got a good idea and need R&D support or partnerships, please let us know.”

R&A solution providers may register their interest and send their solution proposals to: info@imda.gov.sg.

R&A initiative

In its announcement, BCA pointed out that R&A will be a key enabler for industry transformation under the digitalisation pillar of the Construction Industry Transformation Map (ITM) supported by the Construction and Facilities Management Industry Digital Plan (IDP) for broad-based SMEs digitalisation.

“Besides improving productivity, digitalisation can also help build up the BE sector’s resiliency. The current Covid-19 pandemic has highlighted the need to accelerate adoption of R&A solutions to reduce dependency on low-skilled manpower,” said BCA.

This latest R&A initiative is funded through IMDA’s Advanced Digital Solutions (ADS) support. Successful BE SMEs and larger enterprises will be provided with up to 80% funding support for qualifying costs to adopt these integrated solutions. BCA also encourages solution providers with ready R&A solutions to step forward and participate in the CFP.

The R&A solutions would support BE enterprises, offering two major benefits: to reduce reliance on low-skilled manpower and increase productivity, and to improve safety at worksites.

A). Reduce reliance on low-skilled manpower and increase productivity

The ongoing Covid-19 situation has made it even more pertinent for the need to reduce reliance on low-skilled workers. Adoption of autonomous R&A solutions by BE firms can potentially bring long-term sustainable benefits to the firms and the BE sector.

Potential R&A applications could help to improve productivity by automating and speeding up various labour-intensive and trade specific tasks like painting, drilling and carrying materials on-site.

B). Improve safety at worksites

The use of R&A solutions could automate trade-specific tasks and provide opportunities to improve workplace safety and health. Specifically, R&A could reduce the risk of falls from height and injuries associated with lifting and transporting heavy equipment within the worksites.

Potential applications of R&A solutions include work at height such as facade maintenance and inspections.

Ecosystem ready for R&A solution providers

BCA has also put in place an ecosystem to support R&A solution providers from early research and innovation stages through to downstream deployment. Some supporting initiatives include :

Built Environment Living Laboratory Framework (BE LLF)

The programme was launched last year to facilitate test-bedding of R&A solutions in living laboratories, allowing built environment firms to trial new emerging technologies. According to BCA, more than 30 innovative proposals have been submitted by more than 10 companies. Examples of available test-bedding sites include Punggol Town and Jurong Lake Gardens.

Building Innovation Panel (BIP)

The programme was formed in 2011 as a multi-agency platform to facilitate in-principle acceptance (IPA) for innovative building solutions that may meet with some regulatory challenges. The scope of the BIP was expanded in 2019 to include areas like R&A, advanced and sustainable building materials, and green building technologies.

According to BCA, the BIP has so far helped obtain IPAs for two R&A solutions, 52 prefabricated prefinished volumetric construction (PPVC) and 46 prefabricated bathroom unit (PBU) systems for adoption in local projects.

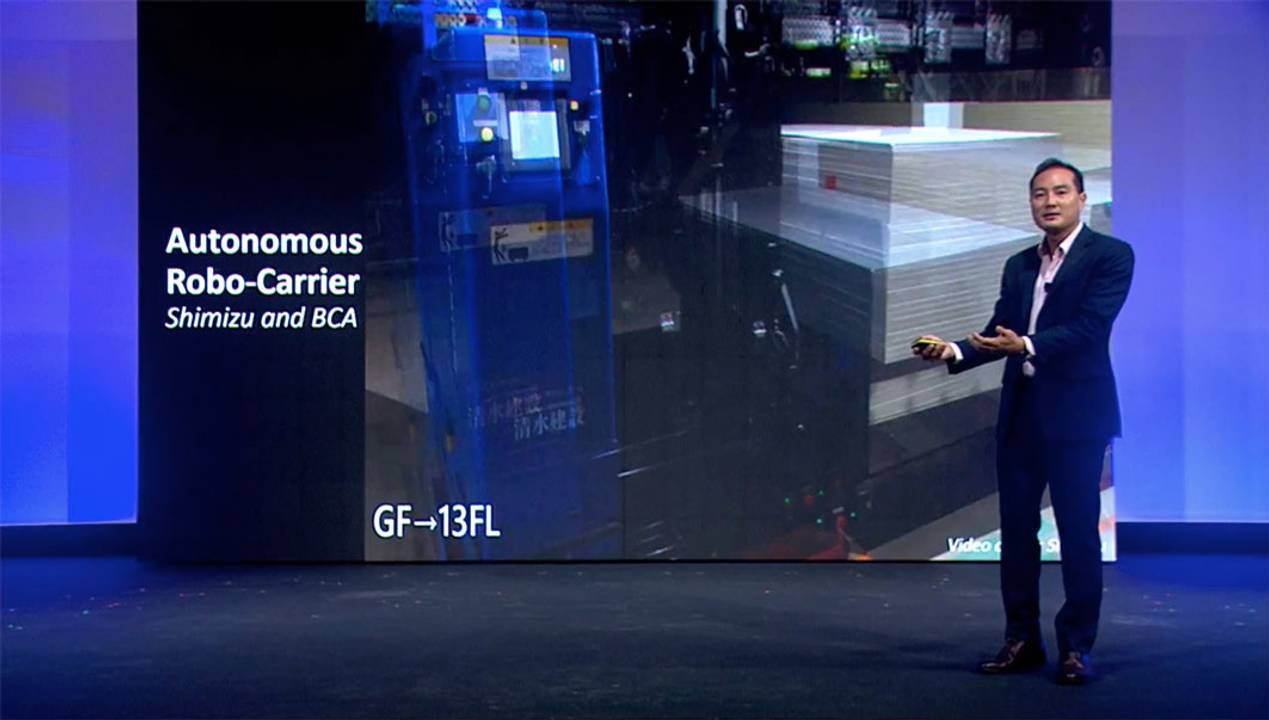

One of the two R&A solutions that obtained IPA was an autonomous Robo-Carrier developed by Shimizu. Construction materials up to 1,000 kg in weight could be transported by the robot from the loading bay to the designated location (i.e. same floor or different floor based on a predetermined route planned by builders). The Robo-Carrier is projected to improve site productivity by at least 30% and will be deployed at Mount Alvernia Hospital Extension project in Q4 2021.

Submit your proposals for R&A solutions: info@imda.gov.sg

For more information:

Built Environment Living Laboratory Framework (BE LLF)

Building Innovation Panel (BIP)

IMDA’s Advanced Digital Solutions (ADS) support